Slipway winches are indispensable equipment in marine operations, crucial for hauling boats in and out of the water. Regular inspection of these winches is paramount to ensure their proper functioning, safety, and longevity. Neglecting maintenance can lead to malfunctions, accidents, and costly repairs. In this comprehensive guide, we’ll delve into the step-by-step process of inspecting slipway winches to guarantee optimal performance and safety.

Understanding Slipway Winches:

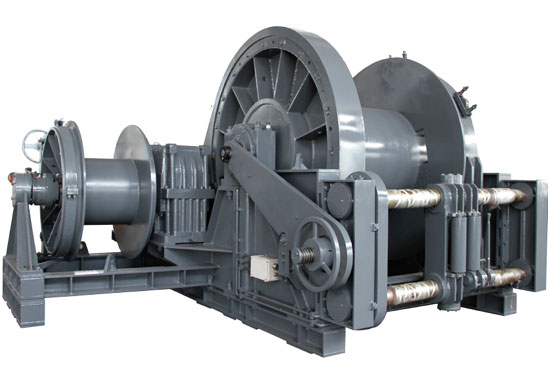

Definition: Slipway winches are mechanical devices designed to haul vessels onto dry land or into the water.

Components: Winches consist of various components such as drums, cables, motors, brakes, and control systems.

Types: There are different types of slipway winches, including electric, hydraulic, and manual variants, each with its specific mechanisms.

Establishing Inspection Procedures:

Schedule: Create a regular inspection schedule based on manufacturer recommendations and usage frequency.

Safety First: Before inspection, ensure the winch is disconnected from power sources and securely immobilized to prevent accidental activation.

Documentation: Maintain detailed records of inspections, including dates, findings, and any corrective actions taken.

Visual Inspection:

External Examination: Inspect the winch for signs of physical damage, corrosion, or excessive wear on components.

Cable Inspection: Check the condition of cables for fraying, kinks, or deformities. Replace any damaged cables promptly.

Brake System: Assess the condition of brake pads and ensure they are functioning correctly to prevent unintended slippage.

Mechanical Inspection:

Drum and Bearings: Examine the drum for smooth operation and inspect bearings for signs of wear or inadequate lubrication.

Gearbox: Check the gearbox for leaks, unusual noises, or excessive vibration, which may indicate internal issues.

Motor: Test the motor for proper functionality, ensuring it starts smoothly and operates without abnormal sounds or overheating.

Electrical Inspection:

Wiring: Inspect electrical wiring for signs of damage, loose connections, or corrosion, ensuring proper insulation and grounding.

Control Panel: Verify the functionality of control switches, emergency stop buttons, and safety interlocks to prevent accidents during operation.

Voltage and Current: Measure voltage and current levels to ensure they are within acceptable limits, indicating proper electrical supply and motor performance.

Hydraulic System Inspection:

Fluid Levels: Check hydraulic fluid levels and quality, topping up or replacing as necessary to maintain optimal performance.

Hoses and Fittings: Inspect hydraulic hoses and fittings for leaks, cracks, or degradation, replacing any compromised components promptly.

Pressure and Flow: Test hydraulic pressure and flow rates to ensure they meet manufacturer specifications, adjusting settings if required.

Load Testing:

Safe Load Capacity: Determine the maximum load capacity of the winch and ensure it is not exceeded during operations.

Load Test Procedure: Conduct periodic load tests using calibrated weights or equivalent loads to assess the winch’s performance under realistic conditions.

Monitoring: Observe the winch during load testing for any signs of strain, abnormal noises, or overheating, stopping the test immediately if any issues arise.

Documentation and Maintenance:

Record Keeping: Document inspection findings, maintenance tasks performed, and any recommendations for future repairs or upgrades.

Preventive Maintenance: Implement a proactive maintenance schedule based on inspection results to address issues before they escalate.

Professional Assistance: Seek the expertise of qualified technicians or engineers for complex repairs or major overhauls beyond the scope of routine maintenance.

Conclusion:

Regular inspection of slipway winches is essential to ensure their safe and efficient operation in marine environments. By following established inspection procedures, addressing any issues promptly, and maintaining detailed records, operators can prolong the lifespan of winches, minimize downtime, and mitigate the risk of accidents. Prioritizing safety and adherence to manufacturer guidelines are key principles in preserving the integrity and functionality of slipway winches for years to come.